Ranger’s success story

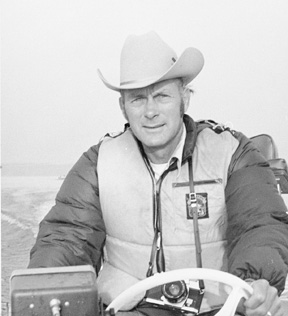

Forrest L. Wood has been described as “the real deal,” “the genuine article” and “a man with unmatched ethics and character.” Add to that a work ethic that is unsurpassed and you have a man who turned a bass-boat company with simple beginnings into one of America’s great success stories.

Ranger Boats Inc., based in Flippin, Ark., celebrates its 35th anniversary in 2003, and the tall, slender man with the signature cowboy hat said he had a very simple formula when he founded the company in 1968.

“We actually just treated people right,” Wood said. “An oversimplification of success in business is to identify what people want, let them know you have it and then treat them right after the sale.”

Wood is emphatic in his belief that the employees at Ranger have led to it becoming a world-renowned boat manufacturer with a reputation for unmatched quality and service. A large percentage of workers at Ranger are local residents who started out 10, 20 or even 30 years ago and never went away.

Wood is emphatic in his belief that the employees at Ranger have led to it becoming a world-renowned boat manufacturer with a reputation for unmatched quality and service. A large percentage of workers at Ranger are local residents who started out 10, 20 or even 30 years ago and never went away.

“We were just able to hire a lot of good ol’ country folk who had the right work ethic and pride in what they were doing,” Wood said. “They were good employees. Loyal employees. Men and women who were intelligent and able to figure things out.”

Such are people like Randy Hopper, who started working at Ranger in high school and eventually became president of the company. Another former high school employee is Gary Howard, who is now director of engineering. The list of names goes on and on.

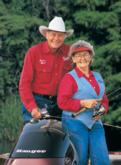

Anyone who is closely associated with Ranger Boats will quickly point to Wood and his wife, Nina, as the cornerstones of the company whose name anglers proudly display on their boats, shirts, trucks and just about anywhere else you can slap a Ranger logo.

In the beginning

High school sweethearts, Forrest and Nina forged a bond early in life that continues to this day. Both came from backgrounds of simple beginnings and lots of hard work. They applied what they learned young in life to a business partnership that began with jobs such as raising cattle, doing building and bridge construction, and operating a very successful fishing guide service on Bull Shoals Lake, the White River and Crooked Creek.

High school sweethearts, Forrest and Nina forged a bond early in life that continues to this day. Both came from backgrounds of simple beginnings and lots of hard work. They applied what they learned young in life to a business partnership that began with jobs such as raising cattle, doing building and bridge construction, and operating a very successful fishing guide service on Bull Shoals Lake, the White River and Crooked Creek.

It was that guide service that eventually led Forrest and Nina into the boat-building business. While they were able to book several float trips during the spring and summer, things would get pretty tough in the wintertime. As Forrest describes it, in order to keep his good guides on the payroll during the winter, they started building some plywood john boats. He knew of a man in town who was covering plywood boats with fiberglass to keep them from leaking, so Forrest thought he would go talk to the gentleman and learn how to do the same thing.

“You just sanded the wood, got it real clean, catalyze the resin, put the cloth on, saturated it, and it adhered to the wood,” he said. “In fact, fiberglass will adhere to just about anything it comes in contact with unless (that item) is waxed properly. One of the first boats we ever made, we didn’t get the mold waxed very good, and it adhered to the mold, and we spent several days getting it released.”

It didn’t take Forrest and his team long to become proficient at waxing the molds after that.

Forrest said that they really just started out making what he described as a “lake boat.” But it so happened that it was the time when bass tournaments were starting up in earnest in the Southeast. He decided to attend one of the tournaments on Greers Ferry Lake to see if anyone was interested in buying boats from him.

“It was the first one I had ever gone to,” Wood said. “Some friends and I went to fish the tournament, and I ended up selling a boat or two.” One of those boats he sold was to Bill Dance, who went on to become a legend on the pro-fishing circuit.

In 1968, Forrest and Nina Wood began Ranger Boats. Forrest had chosen the name Ranger because he felt it was a good, strong name, just like the Texas Rangers and the Army Rangers. The first six boats were built in what is now the local fire house in downtown Flippin. Manufacturing was then moved to an unoccupied dance hall on the edge of town that had been known as the Silver Star. In 1970, Ranger manufactured 1,200 boats that sold for $1,000 each, complete with lights and steering. Demand was high, and orders were streaming in.

In 1968, Forrest and Nina Wood began Ranger Boats. Forrest had chosen the name Ranger because he felt it was a good, strong name, just like the Texas Rangers and the Army Rangers. The first six boats were built in what is now the local fire house in downtown Flippin. Manufacturing was then moved to an unoccupied dance hall on the edge of town that had been known as the Silver Star. In 1970, Ranger manufactured 1,200 boats that sold for $1,000 each, complete with lights and steering. Demand was high, and orders were streaming in.

On May 4, 1971, one of the most infamous fires in Flippin history burned down the Ranger Boats factory. A static spark of electricity or electrical shock ignited acetone, and the fire quickly spread throughout the building. Forrest and a friend were able to get inside the building and salvage 60 boat orders from inside a metal desk.

What happened next has become part of the Ranger legend. Bound and determined to keep his 60 employees on the payroll, Forrest nailed a phone to a tree near the ruins of the plant and began to conduct business while friends helped clean up the rubble. With a lot of determination and perseverance from all the employees, they were building boats again exactly 40 days and nights after the disaster struck. Those 60 orders would be filled.

Even though there were a lot of hurdles to cross, including a tornado and growing debt, business began to flourish for Ranger Boats in the early to mid-1970s. Not by coincidence, that was the same time Wood began fishing the fast-growing Bass Anglers Sportsman Society (BASS) tournament circuit. Even though he proved to be a respectable angler, qualifying for the Bassmasters Classic in 1971 and 1979, he was there to display and sell boats.

“The reason the pros liked our boats is because we custom-built them,” Wood said. “We would build the inside configuration however somebody wanted it. We were fishermen ourselves, and we pretty much understood what people wanted.”

A lot of the pro anglers would sit down with Forrest and draw the design of the boat they wanted on the nearest piece of paper. Many times, he would end up going back to the factory with a sketch on a napkin in one hand and an order in the other. His employees knew what to do after that.

“We wanted to make the best possible product,” Wood said. “We weren’t interested in making something that anyone would buy. We were interested in the top of the market. You get that by making a quality product.”

About the boats

“I vividly remember riding in my first Ranger boat. We put an engine on it and took it to the lake. It was quite an experience for me, and I never forgot it. Sitting in a boat, watching it hit the waves and feeling vibrations – you get a real feel for the boat, and there is no substitute for that.”

“I vividly remember riding in my first Ranger boat. We put an engine on it and took it to the lake. It was quite an experience for me, and I never forgot it. Sitting in a boat, watching it hit the waves and feeling vibrations – you get a real feel for the boat, and there is no substitute for that.”

– Randy Hopper,

President, Ranger Boats

Hopper has had a passion for building a better boat ever since he began working for Ranger more than 30 years ago. He was still in high school when he began work there and remembers being handed a broom the first night of work. Moving from spraying gel coat to working the chopper gun to supervising the night shift, Hopper eventually became president of Ranger Boats in 1989.

He and several longtime employees, along with a dedicated founder, created and implemented some of the most innovative ideas ever integrated into a bass boat. Ranger Boats has been credited with structural designs and performance enhancements that revolutionized the fishing-boat industry.

“We just took some simple ideas and incorporated them into a highly specialized fishing machine,” Hopper said. “People liked what they saw and wanted the boats. People lined up for the boats because they were getting something that was very functional for them and gave them value.”

In the early ’70s, most bass boats were very narrow and straight with a somewhat flat bottom. But the design engineers at Ranger figured out that a V-shaped hull and wider beam would provide for a much better ride and a lot more room for fishermen to move around inside the boats. As the overall design of the boats changed, so did the size. The boats got bigger and bigger.

“I think in the early stages of the bass boat, the horsepower offered on most engines couldn’t really push around our fishing boats,” Howard said. “But as time progressed, they made larger horsepower engines, and the boats got bigger as well.”

“I think in the early stages of the bass boat, the horsepower offered on most engines couldn’t really push around our fishing boats,” Howard said. “But as time progressed, they made larger horsepower engines, and the boats got bigger as well.”

As the engines got bigger, stronger transoms became essential. The early transoms were made of plywood and were subject to rot after constant exposure to water. Even the transoms that were covered with fiberglass tended to leak.

“We just needed something to prevent the rotting and water saturations,” Howard said. “Especially if somebody hung an engine on the boat and didn’t seal it properly, water would get in there and the transom would get mushy and weak. Everybody knew there had to be a better way.”

It was Hopper who found that way. He heard about a process using fiberglass called pultrusion that resulted in a very strong, very consistent material.

“I had an engineering friend that we had done some projects with unrelated to the marine industry, and he was very aware of the potential that existed with pultrusion,” Hopper said. “With the testing that had been done independently and on our own, we saw the strength characteristics of pultrusion and the ability to engineer a product that was exactly the same every time. I had the idea we needed to be building our transoms out of this material.”

Hopper began experimenting with the process (which he describes as “like trying to stuff an oyster into a parking meter”) in 1985. In 1986 he was able to secure a patent on the process as it relates to building transoms, and in 1987 Ranger introduced their first models with pultruded fiberglass transoms. The 2003 Ranger models still feature this innovative design that has stood the test of time.

The pultruded fiberglass transom is just one example of the many innovative and creative designs Ranger has introduced through the years that have greatly improved the durability, feel, performance and overall quality of their fishing boats.

Innovations such as the revolutionary molded fiberglass stringer system; molding the liner of the boat interior in one piece and gluing the consoles in afterwards; creating a VS engine setback design to provide better engine performance; a power distributing transom with integral fiberglass gussets and flotation tanks; and a fluid-driven steering system that has made cable steering almost obsolete are Ranger hallmarks.

Innovations such as the revolutionary molded fiberglass stringer system; molding the liner of the boat interior in one piece and gluing the consoles in afterwards; creating a VS engine setback design to provide better engine performance; a power distributing transom with integral fiberglass gussets and flotation tanks; and a fluid-driven steering system that has made cable steering almost obsolete are Ranger hallmarks.

One of the key concepts Ranger has kept in the design of its boats through the years is what has been termed as a “one-piece feel.” This has been achieved by using foam as the primary flotation material and inserting it into almost every cavity of the boat. The foam is a very strong and rigid material but very lightweight.

“The deck and hull are permanently foamed together to create that one-piece feel,” Hopper said. “It’s not like most other competitors, where you could actually take the deck off the boats. Once ours is together it stays that way. The advantage of that is when you are crossing waves on a lake, you don’t have that resonant sound like a bass drum that comes from two independent parts. It’s a boat that moves together all in one piece.”

It’s about fishing

From the moment that Forrest Wood fished his first bass tournament, Ranger Boats was all about fishing. With safety of the boater in mind, Ranger led the way to new U.S. Coast Guard Flotation Standards in 1972. In 1973, Forrest’s aerated livewell was patented and eventually became standard on Ranger boats.

Another Ranger hallmark is attention to detail, including early additions like carpeting and running rod racks. Over the years, the decks of the boats have been raised and widened to provide more room and to allow for the extended use of certain fishing techniques. There have also been special designs developed to better accommodate fishing equipment like depth finders and trolling motors. Heavy-duty 6-gauge trolling-motor wire was also added to increase efficiency.

Improvements to livewells have taken place, such as the venturi livewell aeration system. Storage compartments have been reinforced for added strength. And, most recently, Ranger introduced STS high-performance seats that provide more comfort. The list seems endless.

A key reason Ranger has been in tune with the needs of fishermen is that so many of the company’s employees fish themselves. “A lot of our employees fish local tournaments,” Hopper said. “In fact, we have one guy who is a supervisor that is a former All-American champion.”

According to Howard: “Our employees like the products, they know the boats and they care about them. I think that makes a big difference.”

Of course, Ranger has never stopped listening to its employees, its pros and, most of all, its customers. “I think you listen as much as you ask, and I think you try to stay ahead of the curve,” Hopper said. “That has been a big part of our success.”

Forrest Wood now spends more time working cattle than actually building boats, but he remains an icon in the fishing industry, as evidenced by the tournament series that bears his name (the Wal-Mart FLW Tour). Forrest, however, is always quick to point out that it is his true love, Nina, who has been the best, most dedicated angler in the family.

“She just dearly loves fishing, and she has done it all her life,” he said. “She has a real passion for it.”

But can she outfish him? “Absolutely,” he said.